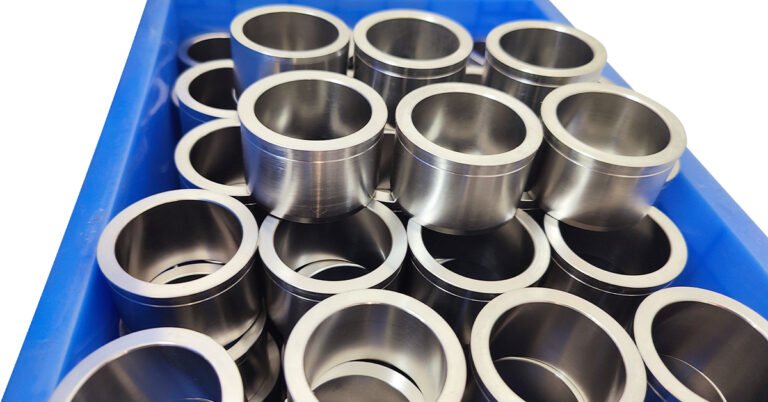

Using Co 6 and Co 12 as a pair of bushings can offer several advantages, including increased wear resistance, improved high-temperature performance, resistance to corrosion and oxidation, and reduced maintenance costs.

Increased wear resistance

Co 12 has a higher level of wear resistance than Co 6, which can help improve the bushings’ overall wear resistance. This is particularly important in applications where the bushings are subjected to high loads, high temperatures, or abrasive environments.

Improved high-temperature performance

Co 12 has better high-temperature performance than Co 6, which can help prevent the bushings’ degradation or failure at high temperatures. This can be important in applications where the bushings are exposed to high temperatures, such as steam turbines or high-temperature pumps.

Resistance to corrosion and oxidation

Co 12 has better resistance to corrosion and oxidation than Co 6, which can help prevent the bushings’ degradation or failure in corrosive environments. This can be important in applications where the bushings are exposed to chemicals or other acidic substances.

Reduced maintenance costs

Using Co 6 and Co 12 as a pair of bushings can help to reduce maintenance costs by increasing the service life of the bushings. The higher wear resistance and improved bushings performance can help reduce the frequency of bushing replacement or maintenance, which can help to save time and money. According to the different designs in your equipment, you can choose one easy bushing to replace to improve the total service life of your equipment.

The chemical components of Co 6 and Co 12

| Alloy | C(Carbon) | Mn(Manganese) | Si(Silicon) | Cr(Chromium) | Ni(Nickel) | Mo(Molybdenum) | W(Tungsten) | Co(Cobalt) | Fe(Iron) | Density | Hardness(HRC) |

| Co 6 | 0.9-1.4% | 1.0%max | 1.5%max | 27-31% | 3.0%max | 1.5%max | 3.5-5.5% | Bal. | 3.0%max | ≥8.30g/cm³ | 38-44 |

| Co 12 | 1.1-1.7% | 1.0%max | 1.0%max | 28-32% | 3.0%max | – | 7.0-9.5% | Bal. | 3.0%max | ≥8.40g/cm³ | 44-49 |

Using both alloys as a pair of bushings, you can use their unique properties to improve performance and reliability. For example, you might use Co 6 as the inner bushing, which is in contact with the shaft or pin, and Co 12 as the outer bushing, which is in contact with the housing or casing. The Co 6 inner bushing can provide good wear resistance and resistance to galling and seizing. In contrast, the Co 12 outer bushing can provide even more excellent wear resistance and resistance to high temperatures and corrosion.

Alternatively, you might use Co 12 as the inner bushing and Co 6 as the outer bushing, depending on the application’s specific requirements. The key is to use the right combination of alloys to achieve the best performance for the particular conditions of the application.

However, the specific advantages will depend on the application’s requirements, and it may be necessary to evaluate each option’s particular benefits and costs to determine the best approach.