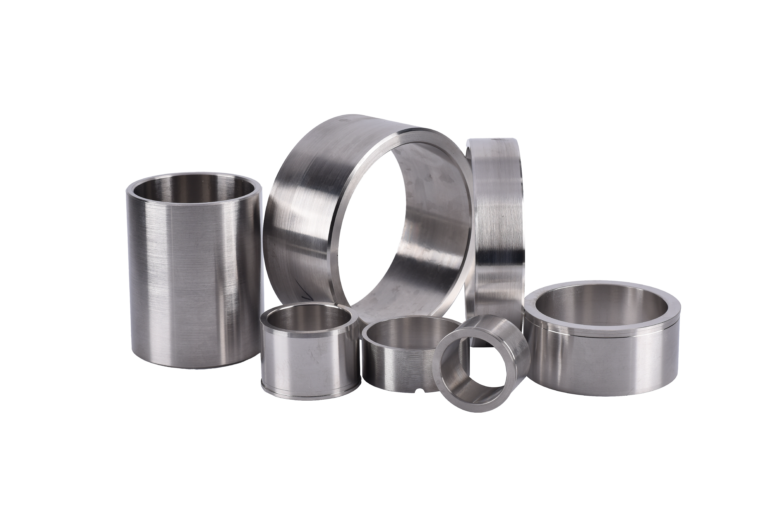

A cobalt alloy bushing is a component that is usually located at the point where the stem meets the body. Cobalt alloy bushings are preferred for butterfly valves as they have excellent wear resistance and can withstand high temperatures and harsh environments. They help extend the valve’s lifespan by reducing the wear on the valve stem, which reduces the frequency of maintenance and repairs. Additionally, cobalt alloy bushings provide a tight seal between the valve stem and valve body, which helps to prevent fluid leakage and ensures that the valve operates efficiently.

Production Process

Cobalt alloy bushings are made by welding, where cobalt alloy Gr.6 is welded onto a base material such as stainless steel or carbon steel. The resulting bushing is machined to the correct dimensions and installed in the butterfly valve. Now, SYTOP supplies solid cobalt alloy products because they will have a longer service life. Solid cobalt alloy is a homogeneous material made entirely of cobalt alloy. It is typically produced by casting or powder metallurgy processes, where the cobalt alloy is melted or compressed into the desired shape. SYTOP can be customized according to your drawings and requirements.

Cobalt Gr. 6 Application in Valve

Cobalt alloy Grade 6 is a standard cobalt-based alloy known for its excellent resistance to wear, corrosion, and high temperatures. It is commonly used in applications where components are exposed to extreme conditions, such as valves. Valves are critical components in many industrial processes, and they must be able to operate reliably under a wide range of conditions. Cobalt alloy Grade 6 is often used to coat valve components such as seats, stems, and discs to improve their wear resistance and extend their service life.

Chemical Composition

| Alloy | C(Carbon) | Mn(Manganese) | Si(Silicon) | Cr(Chromium) | Ni(Nickel) | Mo(Molybdenum) | W(Tungsten) | Co(Cobalt) | Fe(Iron) |

| Co 6 | 0.9-1.4% | 1.0%max | 1.5%max | 27-31% | 3.0%max | 1.5%max | 3.5-5.5%max | Bal. | 3.0%max |